3000w laser welder

I-PARAMETER YOBUCHWEPHESHE

| AMANDLA LASER | 1000W | 1500W | 2000W |

| Ukujula kokuncibilika (insimbi engagqwali, 1m/min) | 2.68mm | 3.59mm | 4.57mm |

| Ukujula kokuncibilika (i-carbon steel, 1m/min) | 2.06mm | 2.77mm | 3.59mm |

| Ukujula kokuncibilika (ingxubevange ye-aluminium, 1m/min) | 2mm | 3mm | 4mm |

| Ukuphakela ngocingo okuzenzakalelayo | φ0.8-1.2 intambo yokushisela | φ0.8-1.6 intambo yokushisela | φ0.8-1.2 intambo yokushisela |

| Ukusetshenziswa kwamandla | ≤3kw | ≤4.5kw | ≤6kw |

| Indlela yokupholisa | ukupholisa amanzi | ukupholisa amanzi | ukupholisa amanzi |

| Ukufunwa kwamandla | 220v | 220v noma 380v | 380v |

| Ukuvikelwa kwe-Argon noma i-nitrogen (okwamakhasimende) | 20 L/min | 20 L/min | 20 L/min |

| Usayizi wesisetshenziswa | 0.6*1.1*1.1m | 0.6*1.1*1.1m | 0.6*1.1*1.1m |

| Isisindo semishini | ≈150kg | ≈170kg | ≈185kg |

Ukusetshenziswa komshini wokushisela we-laser ophethwe ngesandla embonini ye-aerospace

Isingeniso

Embonini ye-aerospace, izinqubo zokushisela ezisezingeni eliphezulu zibalulekile ukuze kuqinisekiswe ukuphepha nokusebenza kwezindiza. Eminyakeni yamuva, imishini yokushisela i-laser ephathwayo ithole ukuthandwa kancane kancane embonini ngenxa yezinzuzo zayo eziyingqayizivele. Lesi sihloko sizonikeza isingeniso esiningiliziwe sokusetshenziswa kwemishini yokushisela i-laser ephathwayo embonini ye-aerospace.

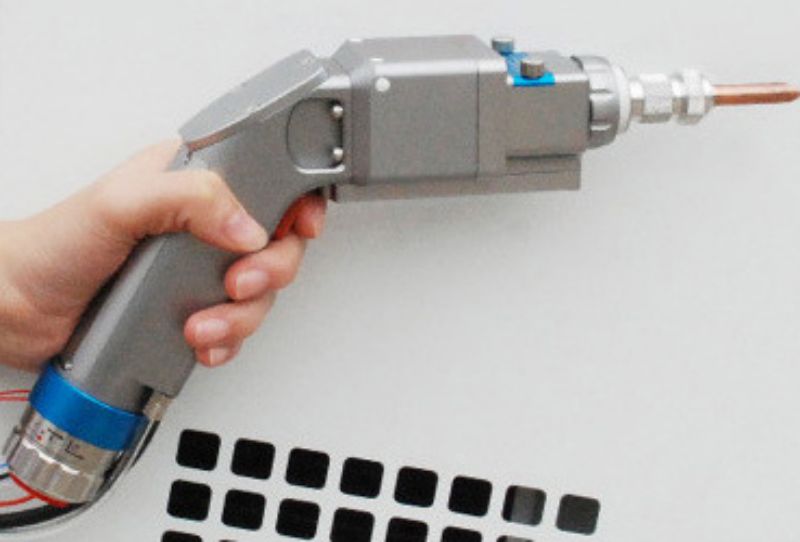

Isingeniso somshini wokushisela we-Handheld Laser

Umshini wokushisela we-laser ophathwa ngesandla uyimishini yokushisela ye-laser ethuthukisiwe esebenzisa umthombo we-laser wamandla aphezulu, odluliselwa ngemicu ye-optical, futhi ehloswe ngokunembile futhi ilungiswe uhlelo oluphambili lokulawula. Umshini wokushisela we-laser ophathwa ngesandla unezinzuzo zokusebenza okulula, ukuguquguquka okuqinile, isivinini sokushisela okusheshayo, kanye nekhwalithi ephezulu yokushisela.

Isicelo embonini ye-aerospace

Ikhwalithi ephezulu yokushisela:Umshini wokushisela we-laser ophathwa ngesandla ungafinyelela ukuhloswa okunembile nokulungiswa, ngaleyo ndlela uqinisekise ikhwalithi nokunemba kokushisela. Embonini ye-aerospace, ukulawulwa kwekhwalithi yokushisela kubaluleke kakhulu, futhi ukusetshenziswa kwemishini yokushisela ye-laser ephathwayo kungathuthukisa kakhulu izinga lokushisela.

Ukusebenza kahle:Umshini wokushisela we-laser ophathwa ngesandla ungaqedela imisebenzi yekhwalithi ephezulu ngesikhathi esifushane, uthuthukise kakhulu ukusebenza kahle kokukhiqiza. Lokhu kubaluleke kakhulu embonini ye-aerospace, njengoba kudinga ukucutshungulwa kwenani elikhulu lezingxenye nezingxenye, futhi izinqubo zokukhiqiza eziphumelelayo zibalulekile ekuqinisekiseni ikhwalithi nenqubekela phambili yokwenziwa kwezindiza.

Ukuvumelana nezimo:Imishini yokushisela i-laser ephathwayo inokuguquguquka okuphezulu futhi ingakwazi ukusingatha izidingo zokushisela eziyinkimbinkimbi. Noma ngabe i-spot welding, i-butt welding, noma i-fillet welding, imishini yokushisela i-laser ephathwa ngesandla ingakwazi ukuyiphatha kalula. Lokhu kuvumelana nezimo kuyinikeza izinzuzo ezinhle ekuphatheni izingxenye zomumo nosayizi abahlukahlukene.

Ukuzivumelanisa nezimo:Umshini wokushisela we-laser ophathwa ngesandla ungavumelanisa nezinto ezihlukahlukene zezingxenye, kuhlanganise nensimbi, okungezona ezensimbi, njll. Lokhu kuvumelana nezimo kuyenza ikwazi ukudlala indima ebalulekile ekuphatheni izinhlobo ezihlukahlukene zezindiza.

Ubungane bemvelo:Umshini wokushisela we-laser ophethwe ngesandla awukhiqizi izinto eziyingozi ngesikhathi senqubo yokushisela futhi uhlangabezana nezidingo zemvelo. Embonini ye-aerospace, ubungane bemvelo bubaluleke kakhulu, ngakho-ke ukusetshenziswa kwemishini yokushisela i-laser ephathwayo kungasiza ukunciphisa umthelela emvelweni.

Isiphetho

Izinzuzo zemishini yokushisela i-laser ephathwayo ibenza basebenze kabanzi embonini ye-aerospace. Akukwazi nje ukuthuthukisa ukusebenza kahle kokukhiqiza, kodwa futhi ukubhekana nezidingo ezihlukahlukene eziyinkimbinkimbi ze-welding. Ngasikhathi sinye, ubungane bayo bezemvelo kanye nezici zokonga abasebenzi nazo ziyenza ibe ukukhetha okuhle embonini ye-aerospace. Ngokuthuthuka okuqhubekayo kobuchwepheshe, ukusebenza kanye nemisebenzi yemishini yokushisela i-laser ephathwayo izothuthukiswa futhi ithuthukiswe, futhi ukusetshenziswa kwayo embonini ye-aerospace nakho kuzoba okubanzi nokujulile.

Ukuthuthukiswa kwekhwalithi yokushisela Izindlela zokushisela eziyisithupha

Ingakwazi ukuqedela izidingo ze-welding ezingenakuqedwa ngabashicileli abavamile, futhi i-weld iqinile futhi inhle,Ayikho i-welding slag, akulula ukuguqulwa, emnyama

I-Spot Welding:indawo encane, amandla aqinile, imodi ye-welding yendawo ingasetshenziswa uma impahla inezidingo zokungena kwe-welding;

Umugqa oqondile:ububanzi bungalungiswa, impahla inokungena, ekuhlanganiseni i-welding, i-wire feeding welding, i-Positive fillet welding ingasebenzisa imodi yokushisela eqondile;

"O" uhlobo:ububanzi obuguquguqukayo, ukusatshalaliswa okufanayo kokuqina kwamandla; Imvamisa ephezulu lapho welding sheet "O" Welding ingasetshenziswa;

Okuphindwe kabili "O":ububanzi obuguquguqukayo, ukunciphisa indawo yokukhanya, ifanele ukushisela ema-engeli ahlukahlukene;

Unxantathu:Ububanzi bungalungiswa ukuze kuncishiswe indawo yokukhanya kuyilapho amandla emiphetho emithathu efana. Ingxenye ephakathi nezinhlangothi zombili zepuleti zishise ngokuphelele;

"8" igama:qhubeka nokwandisa indawo yokukhanya ngesisekelo sikanxantathu, ukuze ipuleti ishise ngokuphindaphindiwe, inkulu.

Iphethini ethi "8" ingasetshenziselwa ukushisela ububanzi.

Ukupakisha Nokuthumela

Lo mshini wawuzopakishwa ekhreyithi yokhuni eqinile ukuze ithunyelwe emhlabeni wonke, ilungele ezokuthutha zasolwandle, ezomoya kanye nezokuthutha.