I-Handheld Laser Welder ye-Metal

I-PARAMETER YOBUCHWEPHESHE

Isingeniso

Ngokuthuthuka kobuchwepheshe, ubuchwepheshe be-laser welding, njengendlela ephumelelayo nesezingeni eliphezulu, busetshenziswe kabanzi embonini yokwakha umkhumbi. Phakathi kwazo, imishini yokushisela i-laser ephathwayo kancane kancane ithatha isikhundla esiphezulu embonini ngenxa yokuguquguquka nokusebenza kahle kwayo. Lesi sihloko sizonikeza isingeniso esinemininingwane ekusetshenzisweni kwemishini yokushisela i-laser ephathwayo embonini yokwakha umkhumbi.

Isingeniso somshini wokushisela we-Handheld Laser

Umshini wokushisela we-laser ophethwe ngesandla uwukunemba okuphezulu, umshini wokushisela we-laser onamandla amakhulu anezinzuzo zokusebenza okulula, ukuphatheka okuqinile, isivinini sokushisela okusheshayo, indawo encane ethintekile ekushiseni, kanye nekhwalithi ephezulu yokushisela. Ifinyelela i-welding ephumelelayo nekhwalithi ephezulu ngokufaka i-irradiation ebusweni bezinto zokwakha umkhumbi ngemishayo ye-laser yamandla aphezulu.

Inkambu yohlelo lokusebenza

Ukushisela isakhiwo se-Hull: Isakhiwo se-Hull siyingxenye ebalulekile yokukhiqiza umkhumbi, futhi izindlela zokushisela zendabuko zinzima ukuhlangabezana nezidingo zokukhiqiza umkhumbi wesimanje ngenxa yezinkinga ezifana nokusebenza okuphansi kanye nekhwalithi ephansi yokushisela. Ukuvela kwemishini yokushisela i-laser ephathwayo kuye kwathuthukisa kakhulu ukusebenza kahle kokushisela kanye nekhwalithi yezakhiwo zemikhumbi ngenxa yezinzuzo zabo zokunemba okuphezulu nesivinini.

Idekhi nekhabhinethi yokushisela: Idekhi kanye nekhabini yizingxenye ezibalulekile zomkhumbi, ezidinga ikhwalithi ephezulu kakhulu yokushisela. Umshini wokushisela we-laser ophathwa ngesandla ungafinyelela ukushisela okunamandla okuphezulu nokufaka uphawu okuphezulu, ukuhlangabezana nezidingo zokushisela zamadekhi namakamelo.

Ukushiselwa kwamapayipi nezinsiza: Izinga lokushisela lamapayipi nezinsiza lihlobene ngokuqondile nokuphepha nokusebenza kwemikhumbi. Umshini wokushisela we-laser ophathwayo usebenza kahle kakhulu ekushiseleni amapayipi nezinye izinsimbi, uvumela ukushisela okunembayo nokusheshayo.

Ifanele izinqubo ezihlukahlukene zokushisela

Isivinini esisheshayo. akukho ubumnyama. akukho deformation

Ilaser, chiller, isibhamu sokushisela izibuyekezo zesimo sesiphakeli ngesikhathi sangempela

Kulula futhi kulula ukufunda ungakhethi abantu ukuze unciphise izindleko zabasebenzi

Izinga lokushisa eliphindwe kabili nokulawula okuphindwe kabili uthuli olupholisa isivinini nokuvimbela ukujiya

Sekela ukuthuthukiswa kwesibili Ukwesekwa kwamarobhothi okudokha

I-PARAMETER YOBUCHWEPHESHE

| Igama Ledivayisi | I-Handheld Laser Welding Machine | Laser Amandla | 1000w-3000w |

| I-Chiller yamanzi | I-Hanli | Isicelo samanzi ku-Water Chiller | Amanzi Acwebile/Amanzi Ahlanzekile |

| Igesi Lokuvikela | N2/AR | Oi-perating voltage | I-AC220 |

| Wukuphakela | Okuzenzakalelayo | Umswakama we-ambient | Ngaphansi kuka-70% ngaphandle kokujiya |

| Laser wavelength | 1070 土10nm | Oizinga lokushisa le-perating | -10C noma 45C |

| Igebeisicelo | <0.5mm | Mukujula kokuncibilika okukhulu | 8mm |

| Ukuhlosisa nokulungisa | Umsebe we-infrared | Gnjengoba ukusetshenziswa | 20ml/min |

| Automatic welding port isekela | yebo | Liibanga lendawo | 0 ku5mm |

| Ubude befayibha | ejwayelekile 10m | PUlse ububanzi | 0.3mm ~ 10mm |

| Umthamo wokushisela | 0.5-4mm | Iwaranti | 1 unyaka |

Izinzuzo kanye Nemiphumela

Ukuthuthukisa ukusebenza kahle kwe-welding:Uma kuqhathaniswa nezindlela zokushisela zendabuko, imishini yokushisela ye-laser ephathwayo inesivinini esiphezulu sokushisela kanye nokusebenza kahle kwe-deposition, ifinyeza kakhulu umjikelezo wokwakha umkhumbi.

Ukuthuthukisa ikhwalithi yokushisela:Ngenxa yokushisa okuncane okuthintekile kwendawo ye-laser welding, i-microstructure ye-weld iminyene kakhulu, ethuthukisa ikhwalithi ye-weld. Ngesikhathi esifanayo, ukulawulwa okunembile kwemishini yokushisela i-laser ephathwayo futhi kugwema amaphutha angase avele ezindleleni zendabuko zokushisela.

Ukunciphisa izindleko zokukhiqiza:Ukusebenza kahle kwe-deposition ephezulu ye-laser welding kuthuthukisa ukusetshenziswa kwezinto, kunciphisa ukusetshenziswa kwezinto ezibonakalayo kanye nokukhiqizwa kwemfucuza, futhi kunciphisa izindleko zokukhiqiza.

Ukuthuthukisa ukuphepha kokukhiqiza:Izindlela zokushisela zendabuko zingadala izinto eziyingozi njengokukhanya kwe-arc kanye nentuthu ngesikhathi sokusebenza, okubeka usongo empilweni yabasebenzi. Ngesikhathi senqubo ye-laser welding, asikho isizukulwane sokukhanya kwe-arc, intuthu, njll., okuthuthukisa ukuphepha kokukhiqiza.

I-Outlook

Ngokuthuthuka okuqhubekayo kobuchwepheshe, ukusebenza nokusebenza kwemishini yokushisela i-laser ephathwayo kuzothuthukiswa. Ukusetshenziswa kwayo embonini yokwakhiwa kwemikhumbi kuzokwanda kakhulu, kungagcini nje ngokushiselwa kwezakhiwo zemikhumbi, amadekhi namakhebhini, amapayipi kanye nezinsiza, kodwa futhi kwandiswe emikhakheni eyengeziwe efana nokuhlobisa ingaphakathi lomkhumbi kanye nokukhiqizwa kwezingxenye. Khonamanjalo, ngokugqugquzelwa kokukhiqizwa okuluhlaza kanye nokukhiqiza okukhaliphile, ukusetshenziswa kwemishini yokushisela i-laser ephathwayo ekukhiqizeni umkhumbi nakho kuzofanelana nemvelo, kusebenze kahle, futhi kuhlakaniphe.

Isiphetho

Ukusetshenziswa kwemishini yokushisela i-laser ephathwayo kuwukuqamba okusha kwezobuchwepheshe embonini yokwakha umkhumbi, ehlinzeka ngokusekelwa okuqinile kokwakhiwa kwemikhumbi ngezinzuzo zayo zokusebenza kahle kanye nekhwalithi. Ngokuqhubeka okuqhubekayo kwezobuchwepheshe, sinesizathu sokukholelwa ukuthi imishini yokushisela i-laser ephathwayo izodlala indima ebaluleke kakhulu embonini yokwakha imikhumbi yesikhathi esizayo.

Isicelo

Umgudu wokungenisa umoya

Insimbi engagqwali evalwe ithangi

Isitoreji Racks

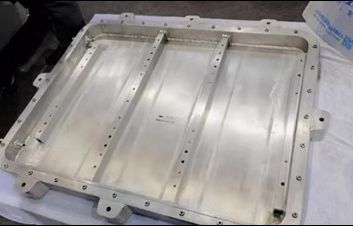

Igobolondo lephrofayela ye-aluminium yezimoto zamandla amasha

Ikhishi kanye negumbi lokugezela ngokwezifiso

Imishini yamanzi ahlanzekile yezokwelapha

Ukupakisha Nokuthumela

Lo mshini wawuzopakishwa ekhreyithi yokhuni eqinile ukuze ithunyelwe emhlabeni wonke, ilungele ezokuthutha zasolwandle, ezomoya kanye nezokuthutha.