I-Handheld Laser Welding Machine yokulungisa isikhunta

Isingeniso Somkhiqizo

Isingeniso

Ngokuthuthuka okuqhubekayo kobuchwepheshe, ukusetshenziswa kwemishini yokushisela i-laser ephathwayo embonini yezokwakha sekuphenduke umkhuba. Le ndlela entsha yokushisela ilethe izinguquko embonini yezokwakha ngenxa yokusebenza kahle kwayo okuphezulu, ukunemba nokusebenza okulula. Lesi sihloko sizonikeza isingeniso esiningiliziwe sezimiso, izinzuzo, kanye nokusetshenziswa kwemishini yokushisela ye-laser ephathwayo embonini yezokwakha.

Uhlolojikelele lomshini wokushisela we-Handheld Laser

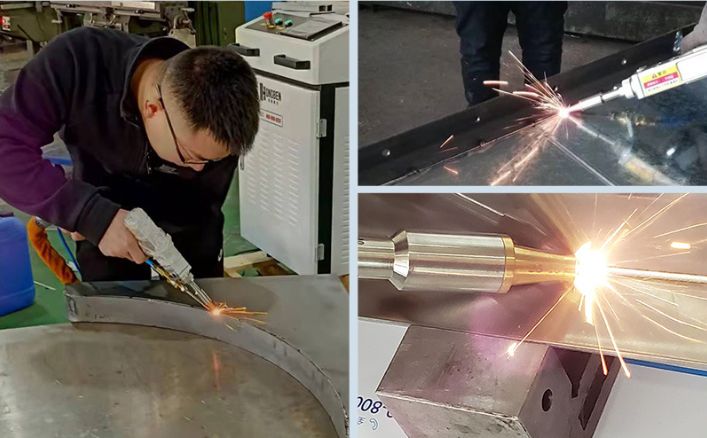

Umshini wokushisela we-laser ophathwa ngesandla uwumshini wokushisela osebenza kahle futhi onembile osebenzisa i-laser njengomthombo wokushisa futhi udlulisa ngemicu ye-optical ukufeza imisebenzi yokushisela ekude nokunemba okuphezulu. Uma kuqhathaniswa nokushisela kwe-arc evamile, ukushisela nge-laser kunomthamo omkhulu wamandla, isivinini sokupholisa ngokushesha, kanye nokungena okujulile, okungafinyelela ukushisela okuphumelelayo nokusezingeni eliphezulu.

Imininingwane Yomshini

Izinzuzo zemishini yokushisela i-laser ephathwayo

Ukusebenza kahle:Ukusebenza kahle kwe-laser welding kuphakeme kakhulu kunokwendabuko kwe-arc welding, okunganciphisa kakhulu isikhathi sokushisela futhi kunciphise izindleko zabasebenzi.

Ukunemba:Ukushisela nge-laser kungafinyelela ukushisela okunembe kwephuzu elingaguquki, kukwenze kube lula ukushisela ubujamo obuyinkimbinkimbi nezakhiwo.

Kulula ukusebenza:Umshini wokushisela we-laser ophathwa ngesandla kulula ukuwusebenzisa futhi ungaqhutshwa ngabasebenzi abathole ukuqeqeshwa okulula.

Ukuvumelana nezimo:Idizayini ephathwa ngesandla ivumela umshini we-laser welding ukuthi usebenze ngokuguquguqukayo ngisho nasezindaweni ezinomkhawulo wesikhala.

Ubungane bemvelo:Inqubo yokushisela nge-laser ayinantuthu, ayinaphunga, futhi ayinamsindo, inomthelela omncane emvelweni.

Ukusetshenziswa kwemishini yokushisela i-laser ephathwayo embonini yezokwakha

Ukushiselwa kwezinsimbi zensimbi:Embonini yezokwakha, ukushiselwa kwemigoqo yensimbi kuyinqubo ebaluleke kakhulu. Umshini wokushisela we-laser ophathwa ngesandla ungaqedela ngokushesha futhi ngokunembile ukumisa nokunqwabelana kwemigoqo yensimbi, uthuthukise ukusebenza kahle kokwakhiwa.

Ukushisela isakhiwo sensimbi:Isakhiwo sensimbi siyifomu lesakhiwo esivame ukusetshenziswa ekwakhiweni kwesimanjemanje, futhi izinga layo lokushisela lithinta ngqo ukuphepha kwesakhiwo. Imishini yokushisela i-laser ephathwayo ingafinyelela izinga eliphezulu lokushisela, ithuthukise ikhwalithi nokuzinza kwezakhiwo zensimbi.

Ukushisela udonga lwamakhethini engilazi:Ukufakwa kwezindonga zamakhethini engilazi kudinga ubuchwepheshe be-welding obunembayo. Umshini wokushisela we-laser ophathwa ngesandla ungafinyelela i-docking ephezulu kanye nokugqagqana, uthuthukise ukusebenza kahle kokufaka nokuphepha kwezindonga zamakhethini engilazi.

Ukushisela amapayipi:Embonini yezokwakha, ukushiselwa kwamapayipi nakho kuyisixhumanisi esibaluleke kakhulu. Imishini yokushisela i-laser ephathwa ngesandla ingafinyelela ukudotshwa kwekhwalithi ephezulu nokugqagqana, ithuthukise ukuphepha nokuzinza kwamapayipi.

I-Decoration Welding:Inani elikhulu lomsebenzi wokushisela liyadingeka ekuhlobiseni, futhi ukuguquguquka nokunemba kwemishini yokushisela i-laser ephathwayo yenza umsebenzi wokuhlobisa usebenze kahle futhi ube muhle.

Isiphetho

Ukuvela kwemishini yokushisela i-laser ephathwayo kulethe amathuba amasha nezinselelo embonini yezokwakha. Isiphenduke indlela entsha nephumelelayo yokushisela embonini yezokwakha ngenxa yokusebenza kwayo okuphezulu, ukunemba, kanye nokusebenza kalula. Ngokuqhubeka okuqhubekayo kwezobuchwepheshe kanye nokwandiswa kwezinkambu zokufaka izicelo, ukusetshenziswa kwemishini yokushisela i-laser ephathwayo embonini yezokwakha kuzoba banzi, kuletha amathuba amaningi okuthuthukisa imboni yezokwakha.

Ijubane lishesha izikhathi ezi-3 ~ 10 kune-welding yendabuko

Hfuthiebanjiwe Li-aserWeldingSuchameCan Rngamunye 120mm/s

Imininingwane Yomshini

I-PARAMETER YOBUCHWEPHESHE

| AMANDLA LASER | 1000W | 1500W | 2000W |

| Ukujula kokuncibilika (insimbi engagqwali, 1m/min) | 2.68mm | 3.59mm | 4.57mm |

| Ukujula kokuncibilika (i-carbon steel, 1m/min) | 2.06mm | 2.77mm | 3.59mm |

| Ukujula kokuncibilika (ingxubevange ye-aluminium, 1m/min) | 2mm | 3mm | 4mm |

| Ukuphakela ngocingo okuzenzakalelayo | φ0.8-1.2 intambo yokushisela | φ0.8-1.6 intambo yokushisela | φ0.8-1.2 intambo yokushisela |

| Ukusetshenziswa kwamandla | ≤3kw | ≤4.5kw | ≤6kw |

| Indlela yokupholisa | ukupholisa amanzi | ukupholisa amanzi | ukupholisa amanzi |

| Ukufunwa kwamandla | 220v | 220v noma 380v | 380v |

| Ukuvikelwa kwe-Argon noma i-nitrogen (okwamakhasimende) | 20 L/min | 20 L/min | 20 L/min |

| Usayizi wesisetshenziswa | 0.6*1.1*1.1m | 0.6*1.1*1.1m | 0.6*1.1*1.1m |

| Isisindo semishini | ≈150kg | ≈170kg | ≈185kg |

Ukupakisha Nokuthumela

Lo mshini wawuzopakishwa ekhreyithi yokhuni eqinile ukuze ithunyelwe emhlabeni wonke, ilungele ezokuthutha zasolwandle, ezomoya kanye nezokuthutha.