I-Handheld Laser Welding Machine

Incazelo

Umshini wokushisela we-Mini Type ophathwa ngesandla we-Fiber laser uhlanganisa izimfanelo ezibalulekile zedivayisi ephathekayo kakhulu nokusebenza okungayekethisi.

I-FTW-SL-1000/1500/2000 I-Mini handheld laser welding machine yamukela isizukulwane sakamuva se-fiber laser futhi ifakwe i-OSPRI handheld laser welding head, egcwalisa igebe le-handheld welding embonini yemishini ye-laser. Ngezinzuzo zejubane lokushisela elisheshayo futhi akukho okudlekayo, ingakwazi esikhundleni sokushisela i-argon Arc(TIG) yendabuko, i-welding kagesi nezinye izinqubo lapho kushiselwa amapuleti ensimbi engagqwali emincane, amapuleti ensimbi, amapuleti angama-galvanized nezinye izinto zensimbi. I-laser ephathwa ngesandla.

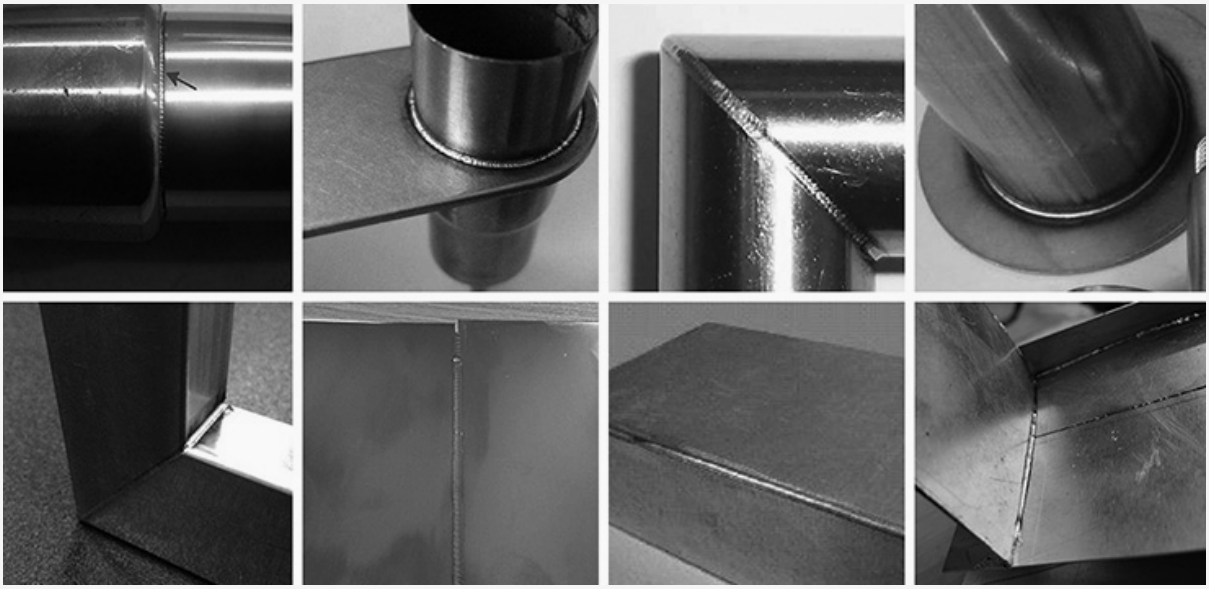

umshini wokushisela ungasetshenziswa kabanzi ezinkambisweni zokushisela eziyinkimbinkimbi nezingavamile ekhishini nasekhishini lekhabhinethi, i-stair lifti, ishalofu, ihhavini, umnyango wensimbi engagqwali kanye ne-window guardrail, ibhokisi lokusabalalisa, ikhaya lensimbi engagqwali nezinye izimboni.

Ipharamitha Yezobuchwepheshe

| Imodeli | I-FTW-SL-1000 | I-FTW-SL-1500 | I-FTW-SL-2000 |

| Laser Amandla | 1000W | 1500W | 2000W |

| Umthombo we-Laser | Raycus/Max/IPG/SUNLITE | Raycus/Max/IPG/SUNLITE | Raycus/Max/IPG/SUNLITE |

| Ikhanda le-Laser | I-OSPRI | I-OSPRI | I-OSPRI |

| Ubude be-Fiber Wire | 5/10 Amamitha | 5/10 Amamitha | 5/10 Amamitha |

| I-Laser Wavelength | 1070nm | 1070nm | 1070nm |

| Imodi yokusebenza | Ukuqhubeka/Modulating | Ukuqhubeka/Modulating | Ukuqhubeka/Modulating |

| I-Chiller yamanzi | I-Hanli/S&A | I-Hanli/S&A | I-Hanli/S&A |

| I-Spot Adjusting Range | 0.1-3mm | 0.1-3mm | 0.1-3mm |

| Ukuphinda Ukunemba | ±0.01mm | ±0.01mm | ±0.01mm |

| Usayizi weKhabhinethi | 744*941*1030mm | 744*941*1030mm | 750*1260*1110mm |

| Isisindo Somshini | Cishe 200KG | Cishe 200KG | Cishe 220KG |

| Amandla kagesi | 110V/220V/380V | 110V/220V/380V | 110V/220V/380V |

Amathiphu Omshini

1. Mayelana Nobude Bekhebula Le-Fiber

Ngokuvamile ubude obujwayelekile bungu-10m, uma unezinye izidingo, sisekela ukufinyeza noma ukunwetshwa.

2. Igesi elisizayo: i-nitrogen noma i-argon

Uma umphumela we-welding surface kudingeka ube mhlophe futhi ukhanye, i-nitrogen noma i-argon iyadingeka.

Uma kungekho sidingo sendawo yokushisela, engeza i-compressed air freeze Dryer, umoya ulungile.

3. Mayelana ne-wire feeder

Ukucushwa okujwayelekile komshini, sizokuthumelela kanye nawo wonke umshini.

4. Iwaranti yomshini

ngokuvamile iminyaka emi-2, sineqembu lochwepheshe ngemuva kokudayiswa, amahora angama-24 ku-inthanethi.

Isicelo somshini

Umshini wokushisela we-Fiber Laser ulungele ukushisela igolide, isiliva, i-titanium, i-nickel, ithini, ithusi, i-aluminium nezinye izinsimbi nezinto zazo ze-alloy. Ingafinyelela ukunemba okufanayo kokushisela phakathi kwezinsimbi nezinsimbi ezingafani. Isetshenziswe kabanzi ku-aerospace, ukwakha umkhumbi, kanye nezinsimbi. Imikhiqizo yemishini nekagesi, izimoto nezinye izimboni.

Imininingwane Yomshini

I-RAYCUS MAX SUNLITE Umthombo we-Fiber Laser Ongakukhetha

Uma kuqhathaniswa nemikhiqizo efanayo, i-RAYCUS MAX SUNLITE Fiber laser Source inekhono eliphezulu lokuguqula i-photoelectric perfor-mance, i-stablebeam, kanye nekhono eliqinile lokulwa nokubukisa.

Amandla we-laser ozikhethela wona asukela ku-1000 watts kuya ku-2000 watts. Sinethimba le-R&D elisebenza kahle nelinobuchwepheshe kanye nethimba elikhiqizayo, okuyikhwalithi ephezulu eChina. Ama-laser anokuguqulwa okuphezulu kwe-electro-optical.

I-OSPRI (QILIN) I-Fiber Laser Welding Head

1. Swayipha ikhanda lokushisela

Inqubo ukuthi ikhanda lamagnetic lendabuko alikwazi ukuqedela, inhloko ye-welding ye-swing idinga kuphela ukusebenzisa i-70% yamandla, engasindisa izindleko ze-laser; Ngaphezu kwalokho, indlela ye-welding ye-swing iyamukelwa, ububanzi bejoyinti le-welding buyalungiseka, futhi ukubekezelelana kwe-welding kunamandla, okwenza kube nokushiyeka okuncane kwe-laser welding joint. Ububanzi bokubekezelela kanye nobubanzi be-welding yezingxenye ezicutshunguliwe ziyakhuliswa, futhi umphumela omuhle wokwenza i-welding uyatholakala.

2. 360 degree micro welding

Ngemuva kokuthi i-laser beam igxilile, iphuzu lingabekwa ngokunembile futhi lisetshenziselwa ukushisela kweqembu lama-workpiece amancane namancane ukuze kuzuzwe ukukhiqizwa okukhulu.

3. Ephathwayo laser Welding ikhanda Imibhobho

Uma sinomshini wokushisela we-laser ophathwa ngesandla futhi sishintsha umlomo wombhobho ngombobo wokusika, singawubiza ngokuthi umshini wokushisela we-laser ophethwe ngesandla kanye nomshini wokusika. Akulona igama elihle!

Ingathatha i-fiber optical kusuka ku-fiber laser futhi iyiqoqe endaweni encane ukuze ikhiqize i-laser enamandla kakhulu ngenjongo yokusika. Nokho, sicela uqaphele ukuthi ayikwazi ukusika impahla ewugqinsi kakhulu.

Ikhwalithi ephezulu ye-Ospri Wobble Welding Head

1. I-wobble welding joint eyakhiwe ngokuzimela isebenzisa imodi ye-welding.

2. Ububanzi bendawo ekhanyayo bungalungiswa.

3. Ukubekezelelana kwephutha lokushisela kunamandla, okwenza kube nobubi bendawo encane yokushisela i-laser, kwandise ububanzi bokubekezelelana nobubanzi be-weld bezingxenye ezicutshunguliwe, futhi kuthola ukubunjwa kwe-weld okungcono.

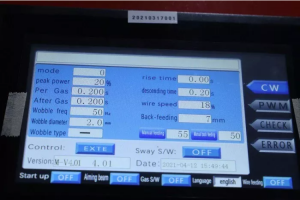

OSPRI Control System

Isistimu yokulawula ye-OSPRI iklanyelwe ngokukhethekile ukuncintisana nekhanda layo le-OSPRI laser welding. Iza nezinhlobo ezimbalwa zemodi, imodeli ye-CW, imodeli ye-PWM ye-Arc.

Isikrini sokulawula sisetha ngokuqondile ngedijithali imingcele yesiphakeli socingo.

Uhlelo luqapha isimo sokusebenza ngesikhathi sangempela, luqaphe futhi luqoqe isimo sokusebenza se-laser, chiller, nebhodi lokulawula.

Sekela izinhlelo zesiShayina, isiNgisi, isiKorea, isiJapane, isiRashiya, isiFulentshi, iSpanishi, isi-Israel.

I-HANLI Water Chiller YE-LASER WELDER (NGOKUZITHANDELA)

I-Hanli Water Chiller Yenzelwe ngokukhethekile imishini ye-fiber laser, umphumela omuhle kakhulu wokupholisa. Ukusebenza okuzinzile nokuthembekile, izinga lokuhluleka eliphansi, ukonga amandla.

I-Automatic Wire feeder

Isakhiwo sokuphakela izintambo ezimbili senza ukuphakelwa kwezintambo kube bushelelezi futhi kuqine ngaphandle kokuxhuma ucingo; Idizayini ye-chassis evaliwe, enesibambo esikwazi ukuphakanyiswa kanye nesondo lendawo yonke; Isilawuli sokuphakela ngocingo, isibonisi sesikrini se-LED sidlala isivinini sokuphakela izintambo ngesikhathi sangempela; Iphinikhodi yokulawula isivinini esinembe kakhulu, kanye nokulawulwa okuhle kwejubane lokuphakela ucingo.

1000W kanye ne-1500W isekela i-0.8mm 1.0mm 1.2mm wire, 2000W isekela 0.8mm kuya ku-1.6mm.

Isivinini sokuthumela nesokubuyela emuva silungiswa ngephaneli yokuthinta.

Uma ezimbili weld igebe metal ezingaphezu kuka 0.2mm ezidinga filler wire.

Inzuzo Yomkhiqizo

I-FIBER LASER WELDING Vs. I-TIG Welding evamile

I-FIBER LASER WElding

Ukusebenza okulula, kunciphisa kakhulu izindleko zabasebenzi.Imisebe engaqondile incane. Isivinini esisheshayo nokusebenza kahle izikhathi ezingu-3-8 kune-argon arc welding.Amandla agxilile kanye nethonya elincane le-thermal deformation.I-welding seam enhle, ichibi elincibilikile elijulile, amandla aphezulu. Izinto ezincanyana kakhulu zingashiselwa, njengensimbi engagqwali engu-0.05mm.Kokubili i-autogenous welding kanye ne-additive welding KULUNGILE.

I-TIG Welding evamile

Izidingo zomsebenzi nezobuchwepheshe ziphezulu, okuholela ezindlekweni eziphezulu zabasebenzi. Ukulimala okukhulu emzimbeni womuntu. Ihamba kancane futhi ingasebenzi kahle. Ithonya elishisayo likhulu, okuholela ekuguqukeni okukhulu. I-welding seam ilukhuni futhi ayijwayelekile. Idinga ukugaywa nokupholishwa. Ayikwazi ukushisela izinto ezincane kakhulu. I-Consumables welding wire iyadingeka. Kulula ukungena.

Ipharamitha ye-Welding Materialngereferensi yakho, izinto ezisetshenziswayo ezahlukahlukene, amapharamitha wokushisela ahlukene, anqunyelwe isigaba, bonisa ingxenye ngokuqondile.

Uma ufuna ukwazi okwengeziwe ngepharamitha, sicela usithinte ngokuqondile, amahora angama-24 ku-inthanethi.