Laser Welding Machine imishini yezokwelapha

Izici zomshini:

Ukusetshenziswa komshini wokushisela we-Laser embonini yedivayisi yezokwelapha

Imishini yokushisela i-laser, njengobuchwepheshe bokushisela obuphambili, isetshenziswe kabanzi embonini yemishini yezokwelapha. Okulandelayo isingeniso esiningiliziwe sokusetshenziswa kwemishini yokushisela i-laser embonini yemishini yezokwelapha.

Ukushiselwa kwezinsimbi zokuhlinza

Imishini yokushisela i-laser idlala indima ebalulekile ekwenziweni kwezinsimbi zokuhlinza. Izinsimbi zokuhlinza zidinga ukunemba okuphezulu nokuthembeka ukuze kuqinisekiswe ukuphepha nokusebenza ngesikhathi sokuhlinzwa. Imishini yokushisela i-laser ingafinyelela ukushisela okunemba okuphezulu, iqinisekise ikhwalithi nokuvumelana kwephuzu ngalinye lokushisela, futhi igweme izinkinga ezifana nokuguqulwa nokuqhekeka okubangelwa izindlela zokushisela zendabuko. Ngasikhathi sinye, imishini yokushisela i-laser nayo ingafinyelela ukushiselwa kwezinhlobo ezahlukahlukene zamathuluzi okuhlinza, ihlangabezane nezidingo zokuhlinzwa okuhlukile.

Ukushisela imishini yamazinyo

Ukwenziwa kwezinsimbi zamazinyo kudinga ubuciko obunembile nezinto ezisezingeni eliphezulu ukuze kuqinisekiswe ukuphepha kwesiguli kanye nemiphumela yokwelashwa. Imishini yokushisela i-laser ingafinyelela ukushisela okunembe okuphezulu kwezinsimbi zamazinyo, igweme izinkinga ezifana nokuguqulwa namaphutha abangelwa izindlela zokushisela zendabuko. Ngasikhathi sinye, imishini yokushisela i-laser nayo ingafinyelela ukushisela izinhlobo ezahlukahlukene zamathuluzi wamazinyo, ukuhlangabezana nezidingo zezinhlobo ezahlukene zokwelashwa kwamazinyo.

Ukushisela izitshalo zamathambo

Ama-orthopedic implants amadivaysi ezokwelapha asetshenziselwa ukwelapha izifo ezifana nokuphuka, okudinga ukwethembeka okuphezulu nokuzinza. Imishini yokushisela i-laser ingafinyelela izinga eliphezulu lokushisela izitshalo ze-orthopedic, igweme izinkinga ezifana nokuguqulwa nokuqhekeka okubangelwa izindlela zokushisela zendabuko. Ngasikhathi sinye, umshini wokushisela we-laser ungafinyelela nezinhlobo ezahlukahlukene ze-orthopedic implant welding, ukuthuthukisa umphumela wokuhlinzwa kanye nezinga lempilo yeziguli.

Ukushiselwa kwemishini yezokwelapha yokungenelela

Imishini yezokwelapha engenelelayo ingamadivayisi ezokwelapha anembayo adinga ukwenziwa nokucutshungulwa okunemba okuphezulu. Imishini yokushisela i-laser ingafinyelela ukushisela okunembe okuphezulu kwamadivayisi wezokwelapha angenele, igweme izinkinga ezifana nokuguqulwa namaphutha abangelwa izindlela zokushisela zendabuko. Ngasikhathi sinye, imishini yokushisela i-laser nayo ingafinyelela ukushiswa kwezinhlobo ezahlukahlukene zemishini yezokwelapha yokungenelela, ithuthukise ukusebenza kahle kokuhlinzwa nokuphepha kwesiguli.

Ngamafuphi, imishini yokushisela i-laser isetshenziswe kabanzi embonini yemishini yezokwelapha, okuletha izinguquko ezishintshayo ekwenziweni kwemishini yezokwelapha. Akugcini nje ukuthuthukisa ukusebenza kahle kokukhiqiza futhi kunciphisa izindleko zokukhiqiza, kodwa futhi kuthuthukisa ikhwalithi yomkhiqizo nokuphepha. Ngokuqhubeka okuqhubekayo kwezobuchwepheshe kanye nesidingo esikhulayo sezicelo esikhathini esizayo, amathuba okufakwa kwemishini yokushisela nge-laser embonini yemishini yezokwelapha nawo azoba banzi.

Imininingwane Yomshini

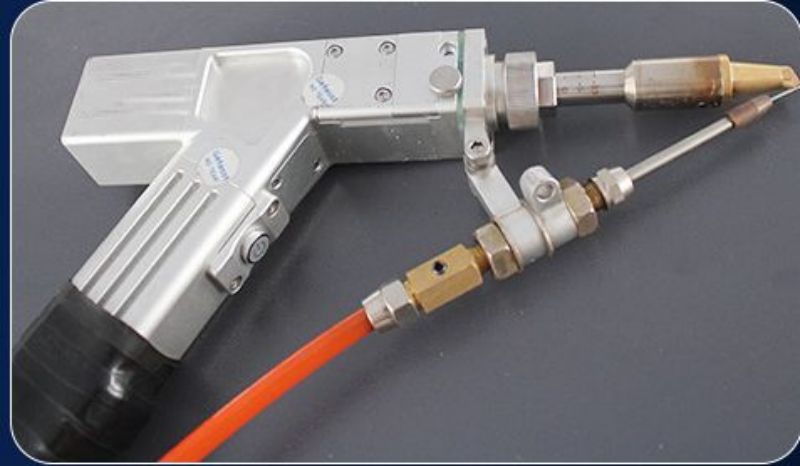

Intelligent welding joint

Isizukulwane sesine sekhanda lokushisela elihlakaniphile sinesisindo esingu-0.8KG kuphela, ukusebenza kwesikhathi eside akukhathali, futhi umklamo womjikelezo wamanzi amabili unomphumela omuhle wokupholisa nokuzinza okuhle.

Amalensi avikela kabili

Ukuphila isikhathi eside, ukuvikela ngokuphumelelayo isibuko sokugxila kanye nekhanda le-QBH, ukunciphisa ngokuphumelelayo ukulimala kwezinye izingxenye zekhanda lokushisela okubangelwa ukusebenza okungalungile lapho i-lens yokuvikela yonakaliswa.

Inkinobho yekhanda lethu lokushisela lesizukulwane sesine isebenzisa ubuchwepheshe bokuphepha ukuthintwa kwengozi ukuze kuvinjwe ukuphuma kwe-laser okubangelwa ukuthinta inkinobho ngephutha, okuphephe kakhudlwana ukukusebenzisa.

I-wire feed nozzle

I-feed nozzle isebenzisa idizayini ephikisana nokuchema ohlelweni lokusebenzisa ukuvimbela ngempumelelo ikhwalithi yokushisela ebangelwa ukuchezuka kocingo lokushisela.

Isistimu yokulawula

Inguqulo ye-V5.2 yesistimu yokulawula ingalungisa ngokushesha imingcele ehlukahlukene yomshini futhi isimo somshini singabonakala ngokucacile. Amapharamitha wenqubo angalondoloza amasethi amaningi edatha ukuze asetshenziswe kalula futhi asekele ukushintsha kwezilimi eziningi

I-fiber laser

Izinhlobo eziningi ze-fiber optic excitation

Idivayisi ye-Optical, ukuze amakhasimende akhethe ngokukhululekile, futhi angakhetha umkhiqizo we-laser ongenisiwe.

I-wire feeder

Ukuthi indawo yokushisela ishiselwa kanjani ibaluleke kakhulu kwi-feeding yocingo, i-wire feeder yenkampani yethu isebenzisa i-stepper motor ukuze ishayele iqinile futhi inamandla, ukugwema ukuphakelwa kwezintambo. Izinkinga ezifana nokudla okungazinzile kwezintambo

I-PARAMETER YOBUCHWEPHESHE

| Umkhiqizo womkhiqizo | I-HRC Laser | Igama lomkhiqizo | Umshini wokushisela we-laser ophathwa ngesandla |

| Indlela yokushisela | Ukushisela okubanjwa ngesandla (okuzenzakalelayo) | ukujula kwe-welding | 0.8-10MM |

| Ububanzi bokushisela | 0.5-5MM | Tousizo ukuthola | ukukhanya okubomvu |

| Igesi yokushisela | I-Argon Nitrogen compressed air (akukho manzi) | isivinini sokushisela | 1-120MM/S |

| Ubude befiber optical | 10M | Ugqinsi lwepuleti lokushisela | 0.3-10MM |

| Imodi yokupholisa | Amanzi apholile | isidingo samandla | 220V/380V 50/60Hz |

| Usayizi wesisetshenziswa | 1200*650*1100MM | Isisindo semishini | 160-220KG |

| Ifomu lokushisela | ukushisela izinqe;i-lap welding;i-rivet welding;welding roll; T welding;i-overlap welding,;welding emaphethelweni,;njll | ||

| Izinto zokushisela | Insimbi engagqwali, insimbi, i-carbon steel, i-aluminium, ingxubevange ye-aluminium, ithusi, ishidi elinothayela | ||

ISIBONISO ESAYIMPELA

Ukupakisha Nokuthumela

Lo mshini wawuzopakishwa ekhreyithi yokhuni eqinile ukuze ithunyelwe emhlabeni wonke, ilungele ezokuthutha zasolwandle, ezomoya kanye nezokuthutha.